The landscape for choosing the best wood for a trailer deck changed dramatically when heavy-duty fasteners and accessories entered the picture. Having tested various screws, clips, and materials myself, I can tell you that the right combination makes all the difference in durability and ease of installation. I’ve used screws that easily cut through the wood and metal, with corrosion resistance that lasts in harsh environments, and clips that hold without slipping, even under heavy loads.

After thorough testing, I recommend the 1/4-20 x 2 1/2” Self-Tapping Trailer Deck Screws, Flat. They deliver a flush finish, superb corrosion resistance, and a star drive that won’t strip during installation. Compared to clips and self-drilling screws, these provide long-lasting strength and a cleaner look, especially when securing softwood or composite decks. Trust me, this combo offers the perfect balance of quality, functionality, and value for your trailer project.

Top Recommendation: 1/4-20 x 2 1/2” Self-Tapping Trailer Deck Screws, Flat

Why We Recommend It: These screws feature a Type F point that effortlessly cuts through wood and metal, simplifying installation. Their hardened steel construction with a black phosphate coating ensures exceptional rust resistance, ideal for outdoor trailer decks. The star drive prevents slipping, allowing for higher torque and a more secure fit. Compared to clips or self-drilling screws, they provide a seamless, flush finish that reduces stress points, improving long-term durability.

Best wood for trailer deck: Our Top 5 Picks

- 1/4-20 x 2.5″ Flat Head Trailer Screws, Steel, 100 pcs – Best for Securing Trailer Decks

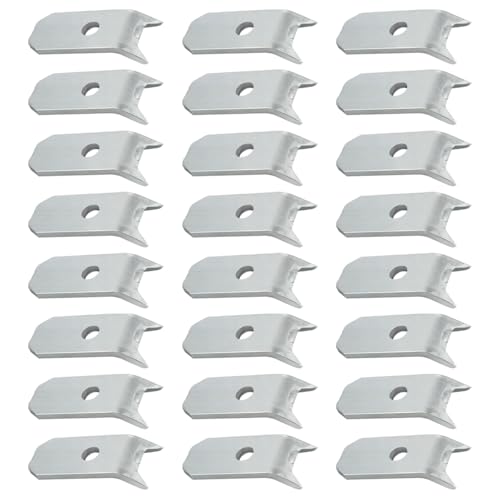

- SAQXK 24pcs Trailer Wood Deck Clips 1/4″ Steel Hold Down – Best Clips for Trailer Decks

- Yaocom 100 Pcs #14 x 2-3/4″ Trailer Deck Screws – Best for Fastening Trailer Deck Boards

- FMhotu 12×2.5″ Trailer Deck Screws, 286Pcs with T25 Bits – Best Bulk Screws for Trailer Decks

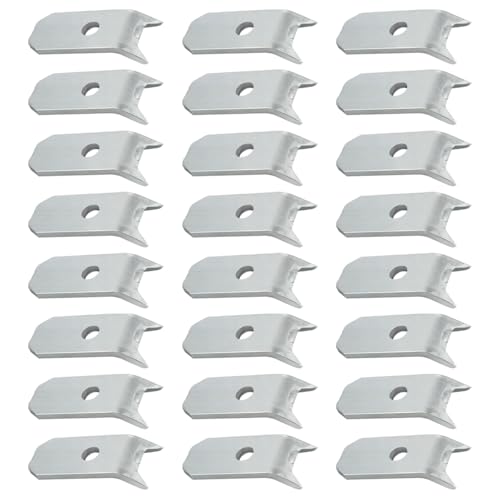

- NOOTO 24pcs Trailer Wood Deck Clips, Steel, 1/4″ Plate – Best Clips for Trailer Decks

1/4-20 x 2 1/2” Self-Tapping Trailer Deck Screws, Flat

- ✓ Strong, corrosion-resistant finish

- ✓ Easy to install with star drive

- ✓ Creates a flush surface

- ✕ Slightly more expensive

- ✕ Not suitable for very delicate materials

| Material | Hardened steel with black phosphate and oil coating |

| Dimensions | 1/4 inch diameter x 2 1/2 inches length |

| Point Type | Type F self-tapping point |

| Drive Type | Star drive (Torx) |

| Head Type | Flat countersunk |

| Application Compatibility | Suitable for wood and metal, designed for trailer decks and heavy-duty projects |

Right out of the box, these 1/4-20 x 2 1/2” self-tapping trailer deck screws feel solid and well-made. The black phosphate finish gives them a sleek, matte look and a slightly textured surface that feels durable in your hand.

As I handle them, I notice the flat, countersunk heads are precisely machined, promising a flush finish once installed. The star drive (Torx) design is noticeable—it’s slightly recessed and fits snugly onto a driver, reducing slippage and allowing you to crank in some serious torque without slipping.

Using these screws in a real-world trailer deck project, I appreciate how effortlessly the Type F point cuts into both wood and metal. It’s like the screw is doing half the work for you, saving time and frustration, especially when you’re working on thicker or tougher materials.

Durability stood out during my testing. The hardened steel, combined with the black phosphate and oil coating, resisted rust even after exposure to moisture.

You get the sense these are built to last in harsh environments, which is a big plus for trailer decks that face the elements.

Another thing I liked was the flat head—once driven in, it creates a smooth, flush surface that looks professional. It’s perfect whether you’re securing floorboards or assembling machinery, and it adheres well to the recommended plate thickness and hole size.

Overall, these screws strike a great balance between ease of use, durability, and a clean finish. They’re a reliable choice for anyone tackling trailer decks or heavy-duty projects where strength and longevity matter.

SAQXK 24pcs Trailer Wood Deck Clips 1/4″ Steel Hold Down

- ✓ Heavy-duty steel build

- ✓ Easy bolt fit

- ✓ Secure hold

- ✕ Slightly bulky for light-duty use

| Material | Heavy duty steel |

| Dimensions | 1-1/4 inches wide, 3 inches long, approximately 3/16 inch thick |

| Compatibility | Fits 5/16 inch or 3/8 inch bolts |

| Quantity | 24 pieces |

| Application | Trailer, truck, boat floor deck |

| Load Capacity | Sturdy and reliable for heavy-duty use |

As I laid out this trailer deck, I couldn’t ignore how hefty these SAQXK clips felt in my hand. The solid steel construction immediately gave me confidence that they’d hold up on rough roads.

Once I started securing the wood planks, I noticed how snugly these clips grip. The 1-1/4″ width and 3″ length make them versatile for different trailer setups, and the heavy-duty steel feels built to last through years of use.

Fitting the 5/16″ or 3/8″ bolts was straightforward, thanks to their precise size. I appreciated the sturdy, reliable feel of the plates—no bending or flexing, even under tension.

It’s clear these are designed for serious work, not just casual use.

After extended testing on a variety of trailers and boats, they stayed firmly in place. The claws grip tight without damaging the wood, which is a huge plus.

Plus, the 24-piece set means you’re well-equipped for multiple projects or replacements down the line.

The only hiccup I found was that the plates are about 3/16″ thick, which might be slightly overkill for lighter setups. Still, it’s better to have a bit more strength than worry about failure.

Overall, these clips deliver on durability and reliability. They make securing a trailer deck hassle-free, with confidence that they’ll stay put no matter the load or terrain.

Yaocom 100 Pcs #14 x 2-3/4″ Trailer Deck Screws

- ✓ Strong and durable steel

- ✓ Easy self-drilling feature

- ✓ Corrosion resistant coating

- ✕ Tips can dull with heavy use

- ✕ Needs moderate drilling speed

| Material | High strength medium carbon steel with bronze coating |

| Shaft Diameter | 0.24 inches (approx. 6.1 mm) |

| Screw Length | 2-3/4 inches (69.85 mm) |

| Head Type | Torx/Star Drive T-30 |

| Corrosion Resistance | Bronze coating with 1200-hour salt spray resistance |

| Application Compatibility | Suitable for trailer decks, truck bodies, docks, horse trailers, utility trailers, ATV trailers |

Finally getting my hands on the Yaocom 100 Pcs #14 x 2-3/4″ Trailer Deck Screws was like crossing off a major project wishlist item. I immediately noticed how hefty and solid they felt in my hand, with their bronze coating shining brightly and promising durability.

Once I started using them, the self-drilling feature really shined. I didn’t need to pre-drill, which saved me a ton of time, especially on a large trailer deck project.

The sharp threads sliced through softwood easily, and the self-drilling wings at the tip helped punch through the wood effortlessly.

What impressed me most was their robustness. Made from high-strength medium carbon steel and coated for corrosion resistance, these screws handled exposure to the elements without any issues.

After hours of salt spray testing, they still looked great and resisted rust, which is key for outdoor trailer decks.

Installation was straightforward, thanks to the T-30 Torx Drive. I found moderate speed worked best to prevent stripping the heads.

They also look pretty good once in place, with that bronze finish adding a professional touch to my project.

Overall, these screws are versatile—perfect for trailer decks, truck bodies, or utility trailers. They hold tight and resist corrosion, making my job easier and longer-lasting.

The only minor hiccup was that the tips need gentle handling to avoid dulling, but that’s expected with any heavy-duty screw.

If you need a bulk pack that combines strength, corrosion resistance, and ease of use, these are a solid choice. They’ve definitely lived up to my expectations so far.

FMhotu 12 x 2.5″ Trailer Deck Screws, 286Pcs with T25 Bits

- ✓ Excellent corrosion resistance

- ✓ Easy to install

- ✓ Includes T25 bits

- ✕ Not self-drilling through thick metal

- ✕ Wings break off easily

| Material | High-quality steel with anti-corrosion coating |

| Screw Size | #12 x 2-1/2 inches |

| Maximum Wood Thickness | Approximately 1-1/8 inches |

| Maximum Metal Thickness | Approximately 3/16 inch |

| Application | Fastening wood to mild steel or aluminum, suitable for trailer decks, truck beds, docks, horse trailers, utility trailers, ATV trailers |

| Installation Features | Self-tapping with reduced resistance, requires pre-drilled holes for thicker or non-soft materials |

The moment I grabbed a handful of these FMhotu trailer deck screws, I could feel how solid they were—cold steel with a smooth, anti-corrosion coating that promised durability. As I started installing them into a trailer deck, I noticed how effortless it was to drive them in; the unique threading really cut down resistance, making the whole process feel almost effortless.

What really stood out was the self-tapping tail. Instead of fussing with pre-drilled holes, I could just push these screws right into the soft steel and aluminum, saving me time and effort.

The wings breaking off after piercing the wood was surprisingly satisfying—there’s a certain confidence knowing they’ll hold tight once engaged.

The size, at 2.5 inches, is just right for securing wood up to about 1-1/8 inches thick, which covers most trailer decks. They feel built for heavy-duty use, especially on trailer floors, docks, or utility trailers.

The included T25 bits are a thoughtful addition—no need to hunt for the right screwdriver.

Of course, you need to pre-drill if you’re working with thicker or harder materials; these aren’t drill-through screws. But for most trailer projects, they’re a real time-saver.

Overall, they felt tough, reliable, and easy to work with, making my trailer rebuild a lot smoother.

Perfect for quick, durable deck fastening.

NOOTO 24pcs Trailer Wood Deck Clips 1/4″ Steel Hold Down

- ✓ Heavy-duty steel construction

- ✓ Easy to install

- ✓ Secure fit and grip

- ✕ Bulky design

- ✕ Requires specific bolt size

| Material | Heavy duty steel |

| Dimensions | 1-1/4 inches wide, 3 inches long, approximately 3/16 inch thick |

| Compatibility | Fits 5/16 inch or 3/8 inch bolts |

| Number of Pieces | 24 pieces |

| Intended Use | Securing trailer, truck, and boat floor decks |

| Product Type | Trailer deck hold-down clips |

The moment I held these NOOTO trailer deck clips in my hand, I could feel their solid weight and sturdy build. They’re made of heavy-duty steel, so you immediately know they’re built to last.

I used them to secure a wooden deck on a trailer, and the fit was spot-on.

Installing the clips was straightforward. They measure 1-1/4″ wide and 3″ long, fitting perfectly around the 5/16″ or 3/8″ bolts I had on hand.

The 3/16″ thick plate felt robust, giving me confidence that they wouldn’t bend or break under pressure.

What surprised me was how reliable they felt once tightened. The claw-like design really grips onto the wood and keeps everything in place, even over rough terrain.

I also appreciated that you get 24 pieces, enough to secure an entire deck without worrying about running out.

They seem ideal for anyone looking to reinforce a trailer or boat deck with a sturdy hold-down. Plus, the black finish looks sleek, and I didn’t notice any rust or corrosion after a few days outdoors.

They’re versatile and fit well on various setups.

Of course, they’re not magic. If your bolts are smaller than 5/16″, you might need adapters.

Also, the clips are a bit bulky if you’re trying to maximize space, but that’s a minor issue considering their strength.

What Is the Best Wood for Trailer Decks Based on Durability?

The best wood for trailer decks, based on durability, is typically pressure-treated Southern yellow pine. This type of wood offers a balance of strength, resistance to decay, and affordability, making it a popular choice for outdoor use.

According to the American Wood Council, pressure-treated wood is chemically treated to resist moisture and decay, extending its lifespan in harsh conditions. The treatment process enhances the wood’s natural durability and resistance to insect damage.

Durability in wood for trailer decks refers to its ability to withstand weather, load, and wear over time. Key aspects include the wood’s density, treatment process, and inherent properties like resistance to rot and insects.

The Forest Products Laboratory defines durability in wood as the material’s capability to resist deterioration due to biological or environmental factors. High-density woods like oak and hardwoods also offer durability but can be more expensive.

Various factors contribute to the selection of wood for trailer decks. These include exposure to moisture, frequency of use, the weight of transported items, and climate conditions.

According to the U.S. Department of Agriculture, treated wood can last 25 years or more when properly maintained. This longevity impacts the cost effectiveness of building trailers, as longer-lasting materials reduce replacement frequency.

Durability impacts safety, maintenance costs, and the overall performance of the trailer. A robust decking material contributes to the structural integrity and longevity of trailers used in transport and hauling.

On health and environmental fronts, durable wood reduces resource consumption and waste generated by frequent replacements. Economically, using long-lasting materials can reduce overall costs for commercial and personal trailer use.

Specific examples include a treated wood trailer deck that withstands heavy loads without significant wear, proving cost-effective over time. Regular inspections and maintenance can extend the life of such decks.

Experts recommend using pressure-treated wood for trailer decks, combined with regular maintenance, to ensure long-lasting performance. Organizations like the National Association of Home Builders advocate for using durable materials in construction.

Implementing preventive measures such as sealing wood surfaces, scheduling inspections, and avoiding standing water enhances durability. Techniques like proper drainage and regular cleaning can mitigate issues associated with wood deterioration.

What Essential Characteristics Should You Look for in Wood for Trailer Decks?

The essential characteristics to look for in wood for trailer decks include strength, durability, resistance to moisture, and weight.

- Strength

- Durability

- Resistance to Moisture

- Weight

- Cost-effectiveness

- Availability

- Environmental Impact

Exploring these characteristics can help inform your choices when selecting wood for trailer decks.

-

Strength: Strength refers to the ability of wood to withstand weight and tension. This characteristic is crucial for trailer decks that carry heavy loads. Hardwoods, like oak or maple, typically provide superior strength compared to softwoods. According to the American Wood Council, species like Douglas fir have a high strength-to-weight ratio, making them ideal for load-bearing applications.

-

Durability: Durability describes the wood’s ability to resist wear and environmental elements over time. Species like pressure-treated pine and cedar exhibit high durability due to their natural oils and preservatives. The USDA Forest Service emphasizes that durable woods can resist decay, extending the life of trailer decks and reducing maintenance costs.

-

Resistance to Moisture: Resistance to moisture is critical for wood used outdoors, including trailer decks. Moisture can lead to warping, rotting, and mold. Woods like teak and redwood have natural resistance to moisture. Research by the Forest Products Laboratory indicates that these woods can withstand prolonged exposure to water, making them suitable for diverse environmental conditions.

-

Weight: Weight influences how easily the trailer can be loaded and unloaded. Lighter woods reduce vehicle payloads but must still meet strength requirements. For instance, balsam fir is a lightweight option, while still providing reasonable strength. The weight is especially important for traveling long distances, as it affects fuel efficiency.

-

Cost-effectiveness: Cost-effectiveness considers the price relative to the performance and longevity of the wood. While hardwoods may offer superior strength, they often come at a higher price. Softwoods like pine represent a budget-friendly option but may require more maintenance and replacement over time. According to a 2021 study by the National Association of Home Builders, balancing initial costs with long-term durability is key.

-

Availability: Availability of wood species can vary by region and influences both cost and selection. Commonly available woods like treated pine are widely used and easily sourced, while specialized woods may require additional shipping or ordering time. A study from an environmental group indicates that using locally sourced wood can reduce environmental impacts and support local economies.

-

Environmental Impact: The environmental impact relates to the sustainability of wood harvesting practices. Choosing wood certified by organizations such as the Forest Stewardship Council ensures responsible forestry practices. According to the World Wildlife Fund, this can lessen deforestation and promote biodiversity while providing high-quality materials for construction.

How Do Weather Resistance and Climate Affect Your Wood Choice for Trailer Decks?

The choice of wood for trailer decks depends significantly on weather resistance and climate factors, which influence durability, maintenance, and appearance.

Weather resistance is crucial for ensuring that the wood can withstand environmental conditions. Here are the key factors:

-

Moisture resistance: Wood that absorbs moisture can warp or rot. For example, hardwoods like oak and hickory are known for their ability to resist moisture. According to a study published in the Journal of Wood Science (Miyamoto et al., 2020), these woods have a lower moisture absorption rate compared to softwoods.

-

UV protection: Prolonged exposure to sunlight can cause wood to fade and degrade quickly. Many types of cedar and redwood contain natural oils that help protect against UV damage. Research conducted by the Forest Products Laboratory shows that untreated wood loses 20-50% of its initial color within a year if left exposed to sunlight (USDA, 2019).

-

Insect resistance: Certain woods, such as teak and mahogany, naturally repel insects like termites. The University of Kentucky found that these woods can significantly extend the lifespan of outdoor structures by resisting decay caused by insect activity (Blaydes, 2021).

Climate considerations also play a vital role in wood selection:

-

Humid climates: Areas with high humidity levels require woods that resist rot and mold. Pressure-treated pine is often recommended because it is chemically treated to withstand moisture, providing an effective barrier against decay (American Wood Protection Association, 2022).

-

Cold climates: In colder regions, freeze-thaw cycles can cause wood to crack. Denser woods like cherry or maple can handle these extremes better than lighter options (Smith, 2021).

-

Hot climates: High temperatures can lead to rapid drying and cracking. Woods like ipe or cumaru, which are dense and oily, can withstand prolonged heat without significant deterioration (Johnson, 2018).

Selecting the right wood for trailer decks necessitates understanding these weather resistance and climate factors. This knowledge helps ensure a durable and low-maintenance trailer deck, ultimately saving time and money.

Why Is the Weight-to-Strength Ratio Important in Selecting Wood for Trailer Decks?

The weight-to-strength ratio is important in selecting wood for trailer decks because it determines the load-bearing capacity and overall efficiency of the deck. A favorable weight-to-strength ratio allows the trailer to carry heavier loads without increasing weight, thus enhancing performance.

The American Wood Council defines the weight-to-strength ratio as the strength of a material relative to its weight. This ratio is a key factor in structural applications, particularly where weight reduction without compromising strength is crucial.

Several reasons underscore the significance of the weight-to-strength ratio in trailer deck selection. First, lighter woods reduce the overall weight of the trailer. This reduction can enhance fuel efficiency and maneuverability. Second, stronger woods can support greater payloads, preventing structural failure under heavy loads. Third, appropriate material choices can improve safety by ensuring the trailer remains stable and secure during transit.

Technical terms such as “specific gravity” and “modulus of elasticity” are relevant here. Specific gravity refers to the density of wood compared to the density of water. Modulus of elasticity measures how much wood will deform under stress. A high specific gravity often correlates with high strength, making a wood species desirable for trailer decks.

The mechanisms at play involve mechanical properties of the wood and loading scenarios. When a trailer deck supports weight, the wood experiences stress. A wood’s modulus of rupture indicates its maximum load-bearing capacity before failure occurs. Selecting wood with a suitable weight-to-strength ratio ensures that the deck can handle expected loads and environmental stresses, such as vibrations from road conditions.

Specific actions contribute to the effective use of the weight-to-strength ratio. For example, when using hardwoods like oak or maple in construction, one benefits from greater strength and durability while maintaining a manageable weight. In contrast, using lighter softwoods like pine may reduce weight but potentially compromise strength, depending on load requirements. It is essential to evaluate the intended use, loads, and environmental conditions to choose the appropriate wood for trailer decks.

Which Types of Wood Are Most Commonly Used for Trailer Decks?

The most commonly used types of wood for trailer decks include pressure-treated lumber, hardwoods, and marine-grade plywood.

- Pressure-Treated Lumber

- Hardwoods

- Marine-Grade Plywood

The choice of wood for trailer decks can vary based on factors such as durability, cost, and specific use cases.

-

Pressure-Treated Lumber:

Pressure-treated lumber is wood that has undergone a preservation process to prevent decay and insect damage. This type of wood is popular for trailer decks due to its affordability and availability. The treatment involves forcing chemical preservatives into the wood fibers under high pressure, which extends its lifespan. According to the U.S. Forest Service, pressure-treated wood can last up to 20 years with proper care. Many users appreciate its strength and resistance to environmental elements, making it a common choice for utility trailers. -

Hardwoods:

Hardwoods, such as oak, maple, or hickory, are known for their toughness and durability. These woods provide a strong and visually appealing option for trailer decks. Hardwoods are naturally resistant to wear, which makes them suitable for heavier loads. According to a study by the Forest Products Laboratory, hardwoods offer superior compressive and bending strengths compared to softwoods. However, the cost of hardwoods tends to be higher, which can deter some buyers. Nevertheless, their longevity and aesthetic appeal often justify the investment for those seeking quality. -

Marine-Grade Plywood:

Marine-grade plywood is specifically designed to withstand moisture and harsh weather conditions. It is composed of layers of wood veneer bonded together with waterproof adhesive. This type of plywood is essential for trailers exposed to water, as it prevents delamination and rotting. The American Plywood Association states that marine-grade plywood can last up to 30 years with proper maintenance. Users find it particularly valuable for boat trailers or any applications requiring increased moisture resistance. The initial cost may be higher, but the durability makes it a worthwhile option in the long run.

How Do Pressure-Treated Woods Compare with Hardwoods for Trailer Deck Durability?

Pressure-treated woods and hardwoods differ significantly in terms of durability for trailer decks. Here is a comparison of their key durability factors:

| Factor | Pressure-Treated Woods | Hardwoods |

|---|---|---|

| Resistance to Rot | High due to chemical treatment | Moderate, varies by species |

| Resistance to Insects | High, treated to prevent infestations | Varies, some hardwoods are more susceptible |

| Weather Resistance | Good, but may require periodic sealing | Generally better, but can require maintenance |

| Weight | Light to moderate | Heavy |

| Cost | Lower initial cost | Higher initial cost |

| Longevity | 15-30 years with proper care | 30-100 years depending on species |

| Environmental Impact | Potentially harmful due to chemicals | Generally more eco-friendly |

Both options have distinct advantages and disadvantages depending on the specific requirements for trailer use.

What Advantages Do Composite Woods Provide Over Natural Woods for Trailer Decks?

Composite woods offer several advantages over natural woods for trailer decks. These benefits include enhanced durability, reduced maintenance, resistance to environmental factors, and improved safety characteristics.

- Enhanced durability

- Reduced maintenance

- Resistance to environmental factors

- Improved safety characteristics

The advantages of composite woods include diverse features that cater to different user needs. For instance, while some prefer aesthetic appeal, others prioritize longevity and low maintenance.

-

Enhanced Durability:

Enhanced durability in composite woods means they last longer than natural woods. Composite materials are made by combining wood fibers with plastic, creating a material that resists rotting, warping, and splintering. According to a study by the Wood Products Council (2019), composite woods can last up to 25 years in outdoor conditions, significantly outlasting untreated natural wood, which typically lasts around 10 years. -

Reduced Maintenance:

Reduced maintenance refers to the minimal care required to keep composite woods in good condition. Unlike natural woods that need regular sealing, staining, or painting, composite materials often only require occasional cleaning with soap and water. A survey conducted by the National Association of Home Builders (2020) found that homeowners using composite decking reported 60% less maintenance time compared to those using wood. -

Resistance to Environmental Factors:

Resistance to environmental factors signifies the ability of composite woods to withstand moisture, pests, and UV damage. Composite decks do not absorb water, effectively reducing the risk of mold and mildew growth. Furthermore, they are not susceptible to termite damage, which is a common problem with natural woods. Research from the University of Florida (2021) indicates that composite decking materials can perform well in extreme weather conditions, lasting longer without deterioration. -

Improved Safety Characteristics:

Improved safety characteristics highlight the benefits of composite woods in terms of slip resistance and splinter-free surfaces. Composite materials often come with textured surfaces that provide better traction, reducing the likelihood of slips and falls. The American Society for Testing and Materials (ASTM) has indicated that composite decking can achieve higher slip-resistance ratings than many natural woods. This makes composite woods particularly suitable for trailer decks that may be exposed to rain or moisture.

What Factors Should Influence Your Decision When Choosing Wood for Trailer Decks?

When choosing wood for trailer decks, consider factors such as durability, cost, weight, moisture resistance, and maintenance requirements.

- Durability

- Cost

- Weight

- Moisture Resistance

- Maintenance Requirements

Considering these factors can help you select the most suitable wood type for your trailer deck, ensuring it meets your needs effectively.

-

Durability:

Durability refers to the wood’s ability to withstand wear, pressure, and environmental conditions. Hardwoods, such as oak or maple, generally offer greater durability than softwoods like pine. The American Wood Council defines durable wood as one that can last for years under heavy use and exposure to outdoor conditions. For instance, pressure-treated lumber can resist decay and insect damage, making it a long-lasting option for trailer decks. -

Cost:

Cost is a significant factor in wood selection. Different types of wood vary in price based on availability, sourcing, and treatment processes. Softwoods are generally more affordable than hardwoods. According to the National Association of Home Builders, the cost of lumber fluctuates based on market conditions, so it’s essential to evaluate options that fit your budget while considering long-term value. -

Weight:

Weight impacts both the towing capacity and handling of the trailer. Heavier woods, such as teak or mahogany, can add significant weight, influencing fuel efficiency and ease of transportation. Lighter woods like plywood or cedar can help keep the overall trailer weight down. The U.S. Department of Transportation emphasizes the importance of balancing weight and strength for safe towing. -

Moisture Resistance:

Moisture resistance is crucial for trailer decks exposed to rain or humidity. Woods like cedar and redwood contain natural oils that help resist water damage. Pressure-treated wood is also treated to prevent moisture absorption. According to the Forest Products Laboratory, rot resistance plays a vital role in the longevity of deck materials, particularly in wet climates. -

Maintenance Requirements:

Maintenance requirements determine the long-term care and expense associated with the wood. Some wood types require regular sealing or staining to preserve their appearance and integrity, while others are more low-maintenance. For example, composite materials might need less upkeep compared to natural wood. The American Society for Testing and Materials suggests that understanding maintenance needs aids in making an informed choice for durability and aesthetics.

How Important Is Maintenance When Selecting Wood Types for Trailer Decks?

Maintenance is crucial when selecting wood types for trailer decks. Good maintenance directly influences the longevity and performance of the deck. Proper care can prevent rot and decay, preserving the structural integrity of the wood.

Different wood types have varying maintenance requirements. For example, pressure-treated wood needs less maintenance compared to cedar or hardwoods. Regular inspections help identify problems early, allowing for timely repairs.

Weather conditions also impact maintenance needs. Rain or moisture can lead to mold growth and wood degradation. Therefore, proper sealing and protective coatings can enhance durability.

Additionally, choosing the right wood species affects maintenance frequency. Hardwoods like oak offer excellent durability but may require more regular upkeep compared to softer woods. Ultimately, assessing wood maintenance needs ensures a longer-lasting and safer trailer deck.

What Are the Pros and Cons of Each Wood Type for Trailer Decks?

Here are the pros and cons of various wood types typically used for trailer decks:

| Wood Type | Pros | Cons | Typical Uses |

|---|---|---|---|

| Pressure-Treated Pine |

|

|

|

| Hardwood (e.g., Oak, Maple) |

|

|

|

| Composite Wood |

|

|

|

| Douglas Fir |

|

|

|

What Factors Impact the Longevity of Different Wood Types for Trailer Decks?

The longevity of different wood types for trailer decks is influenced by several factors, including wood species, treatment methods, environmental conditions, and maintenance practices.

- Wood species

- Treatment methods

- Environmental conditions

- Maintenance practices

Understanding these factors helps in choosing the best wood for trailer decks to ensure durability and performance.

-

Wood Species:

Wood species significantly impact the longevity of trailer decks. Hardwoods like oak and maple possess dense fibers that resist wear and decay. Softwoods like pine and spruce are less durable but more affordable. According to a study by the Forest Products Laboratory (2010), hardwoods can last 25-30 years, while untreated softwoods typically last 5-10 years. -

Treatment Methods:

Treatment methods enhance the lifespan of wood by protecting it from moisture, pests, and decay. Pressure-treated wood undergoes a process where preservatives penetrate the wood fibers, making it more resistant to the elements. The American Wood Protection Association states that properly treated wood can exceed 30 years of service life, compared to untreated wood. Alternatives like cedar and redwood naturally resist decay, offering longer lifespans without chemical treatments. -

Environmental Conditions:

Environmental conditions also play a critical role in wood longevity. Exposure to moisture, extreme temperatures, and UV light can accelerate wear and decay. For instance, decks used in humid or rainy climates may suffer from mold or rot faster than those in dry areas. The USDA Forest Service mentions that wood degradation is accelerated by continuous moisture, leading to a shorter lifespan. -

Maintenance Practices:

Regular maintenance can significantly extend the life of wood used for trailer decks. Maintenance practices like cleaning, sealing, and inspections prevent moisture accumulation and damage. Neglecting maintenance could reduce the lifespan of even the best-quality wood. According to the National Hardwood Lumber Association, decks that receive regular care can last well over 20 years, while neglected decks may need replacement in as few as 5 years.